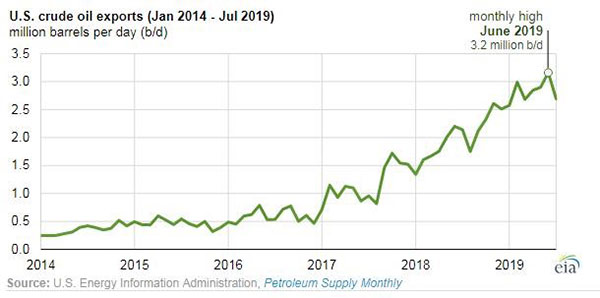

According to a recently released report by eia, the U.S. export of crude oil experienced an evident rise during the first half of 2019, having increased 966,000 b/d compared with the same period last year. Daily export averages 2.9 million b/d and a record-high monthly average has been realized this June at 3.2 million b/d.

As oil production and exports grows steadily, oil & gas companies are paying more attention to the efficiency of operation. Last month, Sung Yun-mo, Korean Minister of Trade, Industry & Energy, and Dr Fatih Birol, IEA Executive Director co-published a commentary, addressing the issues of leading the energy industry with innovation and efficiency.

They highlighted in the article that major shifts are occurring in the energy industry around the world as technologies develops rapidly. Amid such innovation and change, enhancing energy efficiency has emerged as a key challenge for every oil & gas player.

Over the past years, the efficiency has climbed to a new peak due to the introduction of new equipment and advanced technologies.

Anyhow, there is still a great deal of room for improvements in energy efficiency across every country and every sector of the global economy, which can have a large impact on progress towards sustainable energy goals by adopting cost-effective technologies that are already available.

After over 10 years of R&D and field application, Jereh has proved its capacity through a serials of completion & stimulation equipment which cover cementing fleet, frac spread, coiled tubing fleet, nitrogen pumping units and so forth, applicable for global well sites with various operation conditions.

Jereh firmly believes that innovation drives industrial development. Jereh R&D engineers investigate operation sites to dig out actual demands and application challenges in front of the clients and actively endeavor to overcome numerous technical difficulties. By now, the company has successfully developed world’s first set of electric frac spread, world’s largest turbine-driven frac pumper, China’s first remote-control cementing unit, large-flowrate sand blender, twin-truck coiled tubing unit for China’s shale gas exploration, creating values for customers worldwide.

For instance, Jereh draws on previous experience, gradually standardizes the design of high-end oilfield equipment and developed Intelligent Cementing Unit for more efficient operation. The equipment dramatically simplifies operation by achieving automatic slurry mixing with only three steps of "Set, Save and Start".

At the same time, operation performance is visualized to ensure what you see is what you get, more convenient to monitor the wellsite situation in a real-time manner. IAMSTIA3 with automatic control of engine throttle and transmission gear minimizes the possibilities of misoperation and facilitates large-scale integrated control.

As for frac spread, Jereh masters rather comprehensive fracturing solutions to satisfy differentiated demands. This year, the company introduced brand-new electric fracturing fleet for shale gas development.

The fleet runs on electricity generated by gas turbine genset rather than diesel, which brings a greener and more economical way for fracturing operations. More importantly, Jereh 5000QPN plunger pumps is mounted on the unit with brake horsepower of 5000 hp each, featuring high rate and high power. Also, the 10” stroke realizes lower cycles under the same displacement requirement, extending service life significantly. With design power of 10,000 hp, Jereh electric frac pumper achieves higher power density, reducing maintenance and on-site labor while enhancing efficiency remarkably.

Visit www.jereh.com to know more about how we can help you overcome the major challenges in the oil and gas industry.