Today, growing responsibilities and pressures on environmental protection are challenging the whole oil & gas industry. It is a topic that has been going on for years, yet remains a controversial and tough one.

The oil & gas community per se is often regarded as part of the environmental issues, especially when it comes to greenhouse gas emissions, given the context of Paris Climate Agreement. A recent report from IEA, The Oil and Gas Industry in Energy Transitions, has made a strong argument for how the industry needs to get involved in guaranteeing the achieving of global climate targets. The World Energy Outlook Special Report published early this year in January, in addition to outlining current oil and gas industry modes of operations, asserts that the industry must get ready to spare more efforts in energy transition.

The energy transition

What is an energy transition after all? As World Energy Council explains, it is a structural change in energy systems which will takes long time to achieve. According to Wood Mackenzie, the status quo of global energy would be overturned as energy transition develops and a new form of energy source emerges over time. It will drive us away from fossil fuels and puts more emphasis on cleaner energy sources and address more efficient use of energy as well.

Why the transition

One main reason behind the energy transition is to curb global warming, which is reckoned as one of the most important challenge in front of mankind nowadays.

It is reported that 15% of global energy-related greenhouse gas emissions come from the process of oil and gas exploration, production as well as transportation (iea, 2020)。 Under Paris Climate Agreement, global CO2 emission needs to be stopped by 2040 or 2050.

Sustainable Development Scenario, what WEO has brought up, aims to keep the rise of global temperature below 2℃ or even 1.5℃, which is in line with the objective of the agreement.

What can oil & gas companies do?

One simple approach is to speed up the development of new energy sources. Main oil & gas companies are already spending around 5% investment on projects besides oil and gas exploration, most of which went to solar PV and wind.Anyway, as it is predicted by many professional institutes, oil and gas will still take a dominant market share for at least another 20 to 30 years.

In recent Short-Term Energy Outlook released by EIA, energy-related CO2 in the United States is projected to drop annually through 2021 for a third consecutive year of declines, which can be good sign to start with.

Another important step could be slashing operational emissions, especially by converting to cleaner fuels on well sites. It is believed that natural gas is a promising energy resource that is able to deliver less emission and cleaner air. Therefore, many outlooks forecast a continued need for gas to 2040 and beyond, assuming it a catalyst for rapid energy transition.

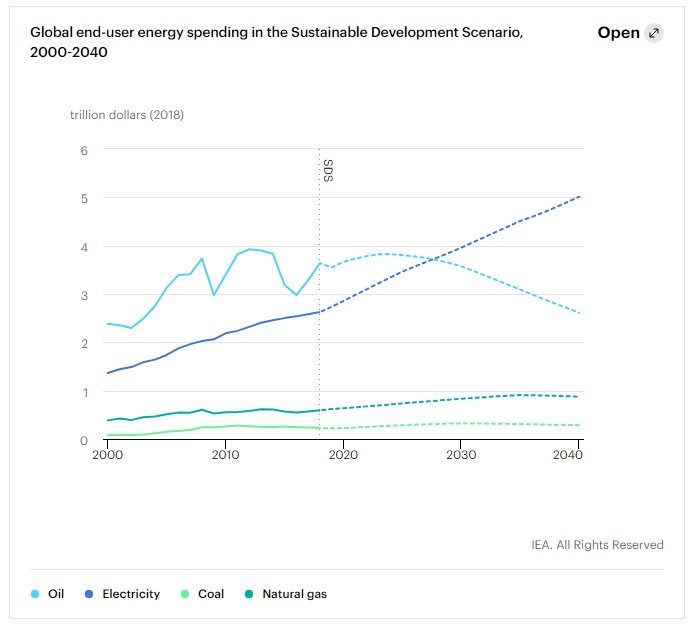

According to the IEA data (as shown below), end-user energy spending of electricity is estimated to overpass fossil fuels (oil & gas combined) before 2040. Meanwhile, electricity is the largest gas consumer in the world, over 24% of which is generated from natural gas.

To make well operation more eco-friendly while remaining efficient, Jereh decided to bring down the emission intensity of oil and gas development by adopting low-carbon gas-fired electricity for well service equipment.

Figure 1: Global end-user energy spending in the sustainable development scenario, 2000-2040

For years, Jereh has been investing on the research and development of electricity-powered well service equipment and has witnessed fruitful achievements.

Based on IEA data, 161.3 pounds of CO2 is produced when per Btu of energy is generated from diesel, while only 117.0 pounds of CO2 from natural gas in the same situation, reducing almost one third CO2 emission.

More importantly, Jereh’s electric frac fleet solution stands out from regular frac equipment for being economical and reducing fuel consumption by 46.7%. Meanwhile, it features amazing power density of 120kw/t, highest among its counterparts.

Since its launch last April, the fleet has attracted much attention within the industry both at home and overseas. The design of the fleet perfectly caters to the demand of lowering emissions and achieving higher power.

E-Frac Fleet Solution consists of E-Frac Unit, E-Sand Blender, E-Hydration Unit, E-Chemical Addictive Unit, Data Van, Sand Conveyor etc. Equipped with two 5,000hp quintuplex pumps, the single unit output of E-Frac Unit is able to reach 10,000 HP, realizing larger power density. Therefore it takes only six E-Frac Units and one gensent to satisfy operation demand, dramatically shortening site rip up time. More importantly, it is estimated that fuel saving is up to 93% by using natural gas.

For more information, please visit Jereh Group official website https://www.jereh.com/