Yantai/June 18,2020, the new generation 7000hp electric frac pumper went offline and passed factory test. Independently developed by Jereh, the product is designed to better serve long-time, high-pressure, large-displacement operation and facilitate the safe, clean, efficient and intelligent development of global oil & gas resources.

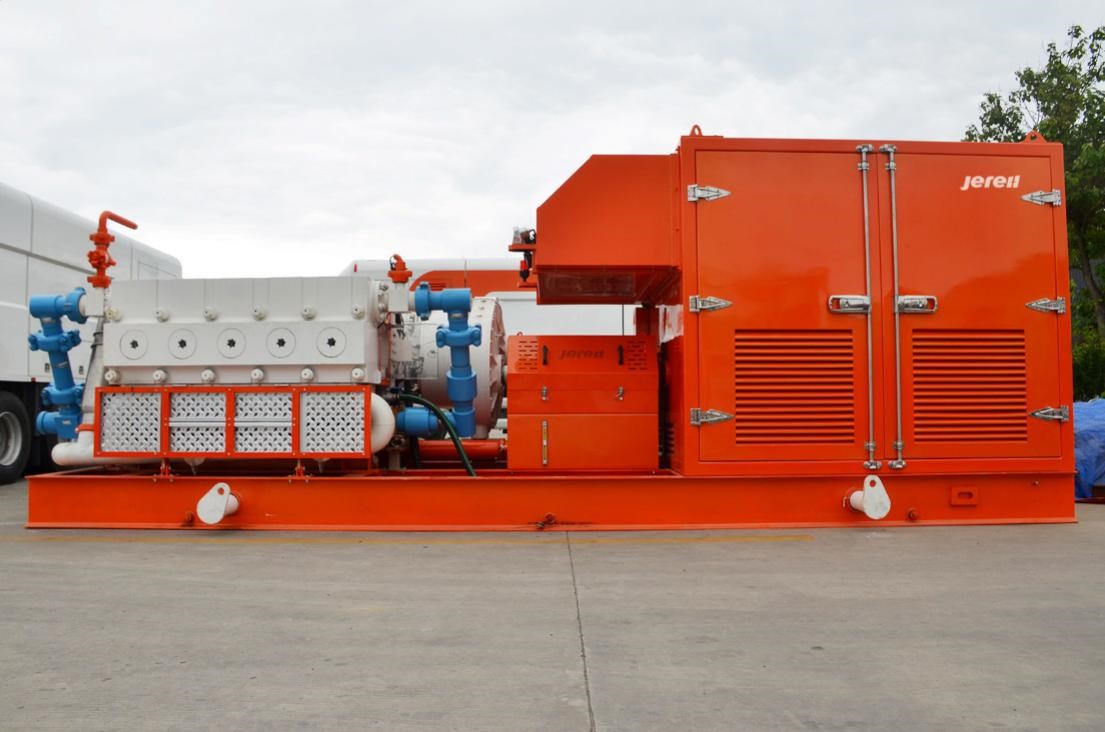

Figure 1: The new generation Jereh 7000hp electric frac pumper went offline and passed factory test.

It owns the biggest power within China, which is up to 7000hp, 3 times of regular 2500hp diesel frac unit.

Last October, the launch of Jereh 7000hp e-frac skid drew much attention from the industry, whereas the new generation has been upgraded with two main optimization.

Quiet operation at the well site is a continuous pursuit. The equipment adopted cabin structure for noise mitigation. It can be reduced by over 22% compared with traditional frac equipment. This provides a safe and cozy working environment for operators and makes continuous operation a reality.

Cabin structure also further reduces the splash from penetrated external manifolds as well as the risks of high-pressure blast, thus ensuring the safety of electricity usage.

Plunger pump, as the core of frac pumpers, is a masterpiece that derives from Jereh’s rich R&D experience and sufficient on-site applications. Jereh R&D team has optimized its design to satisfy long-time continuous operation under heavy load, which includes product structure, key component, lubricating system and so forth to break through the conventional design.

Figure 2: Jereh 7000hp electric frac pumper under test

Having gone through strict tests, the new plunger pump runs stably under different pressure and rotating speed and features lower stroke and longer service life, fully competent for long-time continuous operation.

Figure 3: Jereh electric frac pumpers working in Sichuan Province, China (1)

Equipped with intelligent monitoring system, the operation status of plunger pump could be analyzed in real time. The system is able to forecast breakdowns and remind component durability so as to help decision-making in a quick and timely manner.

Shale gas resources in China are usually buried deep in mountainous areas, where have bumpy roads and scattered residential settlements. Therefore, Chinese shale gas production is evolving towards a high-power, long-time and low-noise mode.

Figure 4: Jereh electric frac pumpers working in Sichuan Province, China (2)

In April 2019, Jereh’s electric fracturing solution for shale gas development was launched, which now have been used in many domestic oilfields.

Also, world’s first 7000hp electric frac pumper that was launched last October is running steadily in Sichuan Province for efficient shale gas development.

“The first-generation 7000hp electric frac pumper is currently operating on high-pressure wells, together with other 5000hp electric frac pumpers. We are quite confident about its performance and can’t wait to witness the operation in person.” said the Deputy Chief Engineer of Jereh.

To sooner realize intelligent and unmanned operation, Jereh shall keep focusing on the R&D of high-end intelligent well service equipment and competitive solution, helping customers cope with the challenges and pressures that they face.

Figure 5: Jereh electric frac pumpers working in Gansu Province, China