A recent report by UK's Oil and Gas Authority (OGA) shows that average unit operating costs have descended from £19 (US$26.47) per barrel (bbl) in 2014, to £12 (US$16.72)/bbl in 2017.

However, eia released latest State Energy Data System (SEDS) this August, which has indicated an increasing tendency of total energy expenditures in almost every U.S. state (eia, 2019). Those states who have more energy-intensive industries witness a higher percentage of energy percentage per dollar of GDP, which was mainly because of rising energy price especially electricity fees.

This kind of paradox somewhat accentuates the importance of improving efficiency and reducing overall cost. This is the reason why Pat Jelinek (2019) estimates that oil industry will increasingly lean on intelligent tools.

For a long time, technology was commonly believed as only a demonstration of a corporate's comprehensive strength. When the trend of smart operation sweeps in, technology strength is going to become the foremost survival skill for companies rather than being the icing on the cake. The whole idea is not new, but it now grows to encompass more concepts including big data, automation, sensors and so forth.

As a leading oil & gas equipment manufacturer, Jereh developed a series of smart tools to solve challenges such as long distance, harsh working conditions and decentralized site distribution, such as integral control system, intelligent tubing analysis system and intelligent remote diagnosis system.

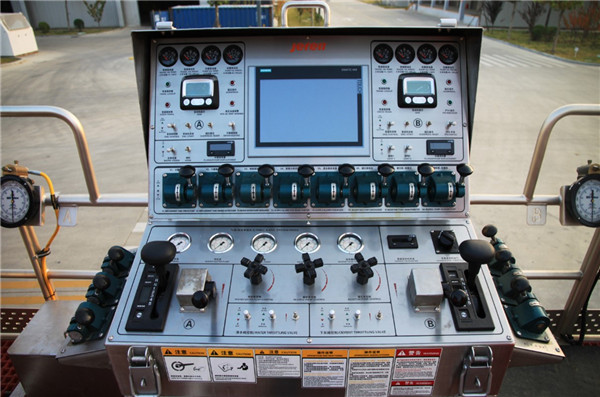

Figure 1: Jereh Data Van to achieve operation monitoring

Mostly applied to Jereh Data Van, the integral control system helps to realize data monitoring, collecting and transmitting among different types of equipment. In this way, equipment operation is easier to be checked through just one control platform. Real-time data display and alarm system guarantee higher safety level and better efficiency.

Figure 2: Integral control system

Sand blender equipped with the system is able to conduct self-regulation automatically based on real-time discharge rate and sand ratio, prominently optimizing operation experience.

With rich experience in applying the entire system to intelligent cementing equipment, Jereh helps clients achieve more centralized operation with less cost on labor. The operation becomes safer as the operating zone is away from both the equipment and high-pressure area.

Figure 3: Intelligent cementing unit

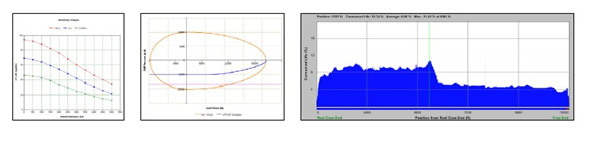

JTAS, or Jereh Tubing Analysis System, is an independent-developed intelligent tool to conduct tubing stimulation analysis as well as engineering designs. It can analyze and predict the force imposed on tubing, fatigue life consumption and pressure gradient during in-hole & out-hole operation. Therefore, the system will greatly improve the effectiveness of risk assessment and design work.

Figure 4: CT Fatigue Life Prediction Module

The remote diagnosis system is designed to connect user's headquarters, Jereh's technical support center and the working equipment. It informs user of the breakdown in advance via detecting components to effectively eliminate potential risks and improve operation reliability.

Backed up by Jereh smart tools, both efficiency and safety can be greatly boosted during operation. Our engineers will analyze the field data and continue to optimize product design. For any advice, welcome to contact us.